Our Whiskey

There’s no faking full bourbon flavor. It has to be earned. So that’s what we do in Clermont: we earn it. We start by selecting the finest grains. And we finish by meticulously aging our whiskey in white oak barrels with maximum char, for an unmistakable richness and signature sweetness. It’s the natural way. And there’s just no cheating nature.

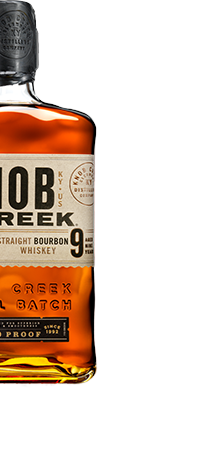

9 YEAR

Bourbon

Whiskey

A benchmark in bourbon. Patiently-aged in white oak barrels for nine years, and bottled at 100 proof.

Learn More

7 Year

Rye

Whiskey

Patiently aged for seven years for the perfect balance between sweet barrel notes and spicy rye character.

Learn More

12 YEAR

Bourbon

Whiskey

Full proof for full flavor. An honest Pre-Prohibition style bourbon.

Learn More

SINGLE BARREL

SELECT BOURBON

From one-of-a-kind barrels specially chosen by your most trusted retailers.

Learn More

Reserve

Single Barrel

Unblended to show off the singular nature of each hand-chosen barrel.

Learn More

SINGLE BARREL

SELECT RYE

A unique Single Barrel Rye specially chosen by your favorite retailer.

Learn More

Kentucky Straight

Smoked

Maple

Naturally sweet and smoky maple fortified by charred oak bourbon.

Learn More

18 YEAR

Bourbon

Whiskey

Our most mature bottling to date, offering a complex yet balanced liquid profile.

Learn More

PATIENCE IS A VIRTUE.

IT’S ALSO OUR MOST

IMPORTANT INGREDIENT.

Find A Retailer